Carton package

Control joints are design elements used in building structures, primarily for managing and controlling cracks in concrete or other building materials. They effectively guide and control the occurrence of cracks by presetting crack locations during construction, reducing random cracks caused by temperature changes, humidity fluctuations, or material shrinkage.

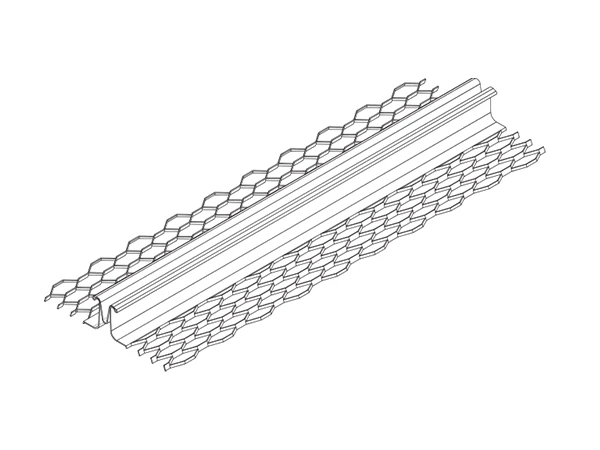

Double-V control joint

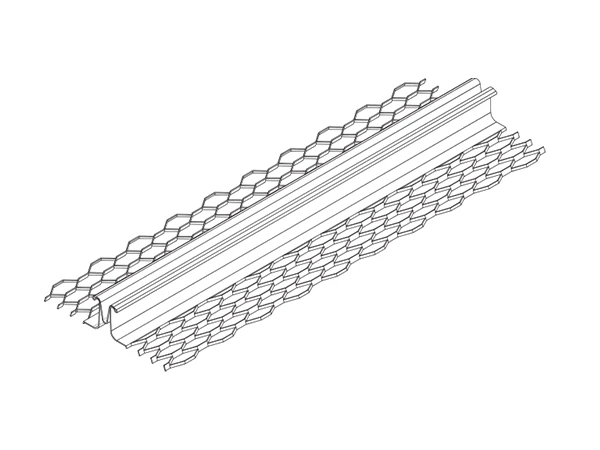

Double-J control joint

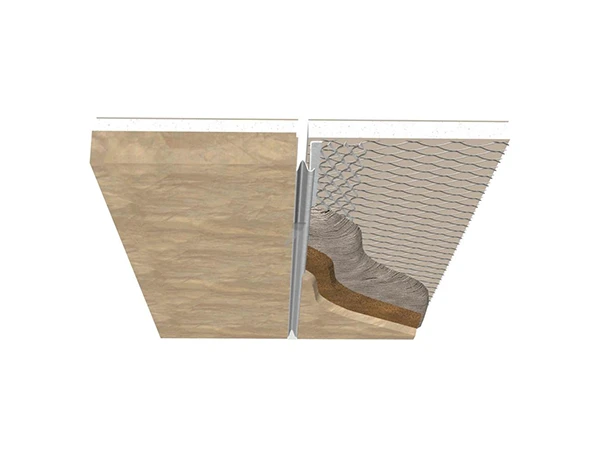

Movement bead

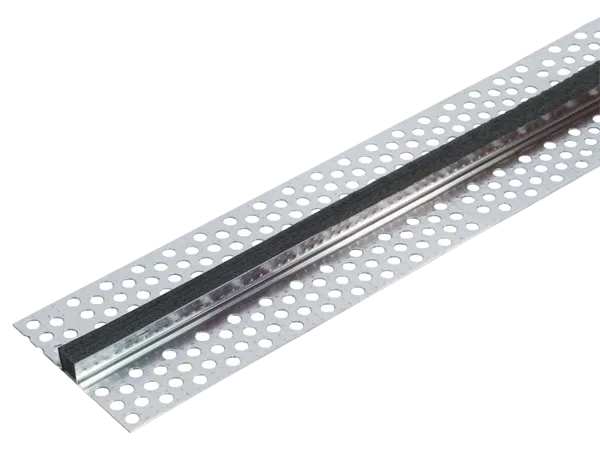

Expansion/Movement Bead

Double-V control joint is used to relieve stress and strains in large plaster area of walls and ceilings. Expanded diamond mesh wings are provided for proper keying and easy application.

This inconspicuous product offers a clean, neat joint in exterior applications. It relieves the stress of expansion and contraction in association with natural shrinkage during stucco curing and basic thermal changes, minimizes crackings in large plastered areas to a large extent and helps to prevent stucco separation at the edge of joints.

| Reference | Plaster Depth (in) | Length (ft) |

|---|---|---|

| VVCJ | 1/4 | 10 |

| 3/8 | 10 | |

| 1/2 | 10 | |

| 3/4 | 10 | |

| 7/8 | 10 |

Similar to double-V control joint, double-J control joint has a 5/16" reveal, rolled outer edge that allows stucco to be fixed under rolled edges to provide increased bonding property and prevent visible separation and cracking. When the stucco is forced under the J flange, this special design helps to reduce stucco separation at the edge of joints.

The joint is taped to prevent stucco from getting caught inside during construction. Then remove the tap easily when the construction is finished.

| Reference | Plaster Depth (in) | Length (ft) |

|---|---|---|

| JJCJ | 1/2 | 10 |

| 3/4 | 10 | |

| 7/8 | 10 |

Movement bead is used to relieve the stress and strain in large plaster area of walls and ceilings and to allow the movement between adjacent surface finishes. Moreover, it overcomes the movement tolerance in plaster, gives a neat render finish and minimizes crackings in plasters to a large extent.

Movement bead is widely used in all kinds of buildings with expansion and contraction joints and is suitable for all kinds of brick and reinforced concrete surfaces.

| Reference | Plaster Depth (mm) | Length (mm) | Material |

|---|---|---|---|

| MBG10 | 10 | 3000 | Galvanized steel |

| MBG13 | 13 | 3000 | Galvanized steel |

| MBG16 | 16 | 3000 | Galvanized steel |

| MBG19 | 19 | 3000 | Galvanized steel |

| MBSS10 | 10 | 3000 | Stainless steel |

| MBSS13 | 13 | 3000 | Stainless steel |

| MBSS16 | 16 | 3000 | Stainless steel |

| MBSS19 | 19 | 3000 | Stainless steel |

Movement Beads are used as a decorative material to cover expansion joints on tile surfaces, especially floors. Expansion joints are a necessary part of the tile surface to prevent cracking and damage caused by the natural expansion and contraction of the tile due to changes in temperature and humidity.

| Reference | Plaster Depth (mm) | Length (mm) | Material |

|---|---|---|---|

| SPE/MB 10 | 10 | 3000 | Galvanized Steel |

| SPE/MB 13 | 13 | 3000 | Galvanized Steel |

| SPE/MB 16 | 16 | 3000 | Galvanized Steel |

| SPE/MB 19 | 19 | 3000 | Galvanized Steel |

| SPE/MB 10 S | 10 | 3000 | Stainless Steel |

| SPE/MB 13 S | 13 | 3000 | Stainless Steel |

| SPE/MB 16 S | 16 | 3000 | Stainless Steel |

| SPE/MB 19 S | 19 | 3000 | Stainless Steel |

| SPE/MB AL | 10/13/16/19 | 3000 | Aluminium |

Carton package

Plastic film package

Wood case package

Loading & shipping